You know how critical it is that your customers get exactly what they ordered. But, sometimes quality control and safety issues can be a major challenge when importing machines from Taiwan.

We can help you!

Twin-gh is a Taiwan based machine tool specialist company that can provide QC inspection service. We have over 15 years of specialized CNC machine tool experience. We know our subject and we pride ourselves on providing, detailed accurate reports so that your customers end up getting what they paid for.

Every defect or safety issues cost you time, money, and your reputation with your customers. When you invest in our machine tool QC inspection service you will have far fewer rejections and you will enjoy increased revenues and customer satisfaction.

When you work with us you will receive a full report. We make sure you have all the information you need to order corrections before the machine is shipped out.

A very important point to mention is that we always take great care, during our machine inspection, to perform it in a very diplomatic and respectful way toward the maker. Our goal is to make sure you receive a compliant machine while maintaining good long term relationship with them.

Pricing

Our standard price for machine tool inspection is 325 USD per day in Taichung county. Most of the machines can be checked in one day.

Our standard price for machine tool inspection is 325 USD per day in Taichung county.

Our pricing

-

Half day of machine consulting in Taichung County $195

-

Full day of machine consulting in Taichung County $325

-

Full day of machine consulting in Taiwan $400

If the machine tool builder is not located in Taichung county

Main control items:

Document audit

We check the order conformity and the different documents of the machine. Manuals are also controlled to be sure there is enough and accurate information in it.

Mechanical check

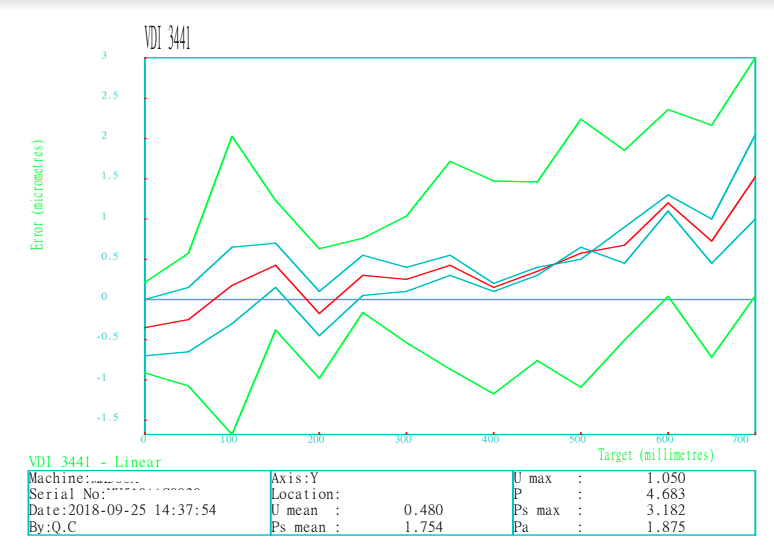

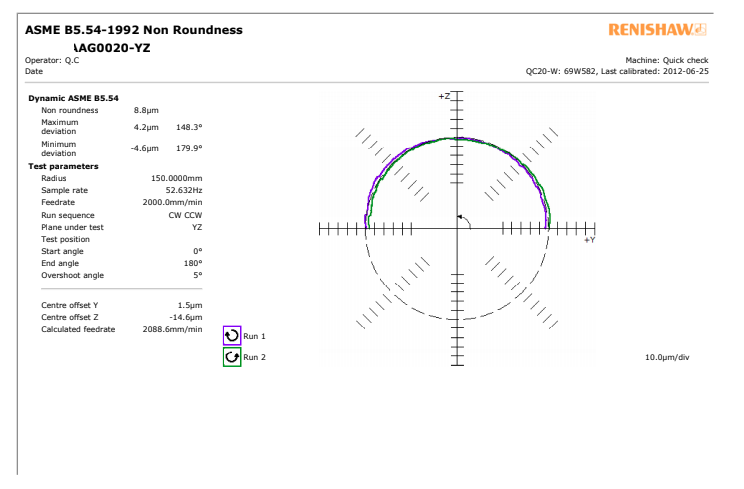

On every machine, we make sure of the proper assembly and function of all mechanical component. The guideways, ball screws, scrappers, lubrication… as well as the dynamic behavior of every axis is checked, and the tool changer stress tested. If it moves, we test it.

Machine geometry

The geometry is checked as per ISO standards. Every point of the norms is measured and compared to the maker report. Upon customer request, we may also execute a cutting test.

Electrical assembly

The electrical assembly of the machine is checked by following our strict checklist. We also ensure the accuracy of the electrical drawing to facilitate future maintenance.

PLC test

Given that the best machine cannot work without a proper PLC and parameters, we follow our strict checklist which is constantly updated to test every possible situation of the machine and make sure there are no mistakes in it.

Safety analysis

For every machine, safety is a very important concern. We make sure it complies with the highest requirements of the destination area as per D2006/42/CE standard for Europe or other countries.